conductING Waste auditS

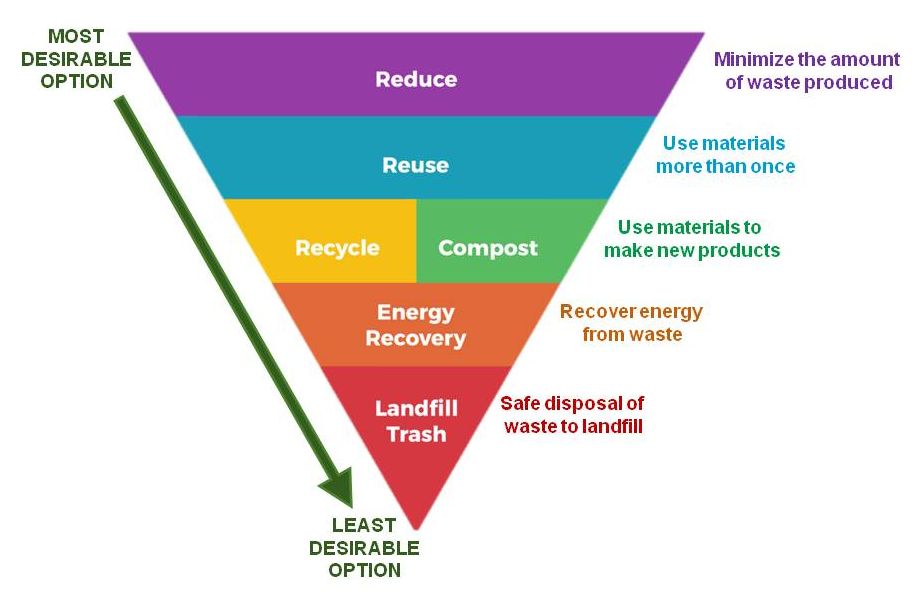

A waste audit is a critical first step in identifying the materials in your waste stream, finding clues as to how the materials got there, determine the possibilities for increased diversion and quantifying the potential cost savings. These audits uncover wasteful purchasing habits, identify improperly sorted materials, and find new revenue streams. More importantly, periodic waste audits are a key tool in verifying the progress of your organization's waste reduction efforts.

|

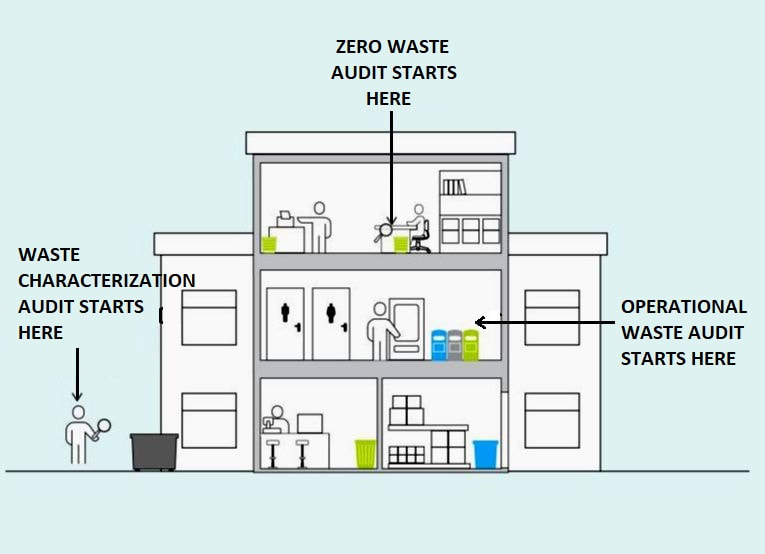

WasteCap offers three primary types of waste audits:

Each audit provides a piece of the puzzle, and can be performed independently but compound their value when performed simultaneously. Each can vary in the level of detail from a simple surface study looking at broad categories (such as trash, recycling, organics) to in-depth analysis identifying each material and its origin. |

OPERATIONAL WASTE Audit

|

An operational waste audit reviews the material handling process for the building or organizational unit. While characterizations and zero waste audits look at the "who, what, and where," the operational waste audits look at the "how and why." Key questions asked:

|

A well executed operational waste audit provides insight on critical failures in the process and ways to reduce contamination. Benefits include critical data for cost/benefit analysis of material handling changes.

Waste Characterization audit

|

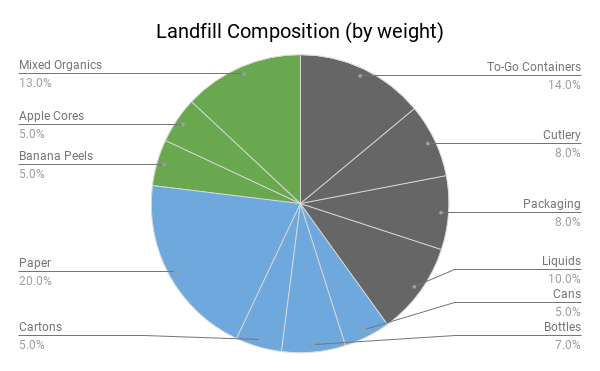

A waste characterization audit is the "macro" view of an organization's waste. It provides a solid foundation for strategic planning efforts and the overall health of the organization's system. The audit gathers all material generated by a building or unit, across each of it's waste streams, and determines:

|

A well executed waste characterization provides data that can be confidently scaled to provide rough estimates of the monthly or annual operational profile, and be used in communication efforts to state the current and potential waste diversion rates of the organization. Benefits also include critical data for cost/benefit analysis of material handling changes and right-sizing collection.

Zero Waste Audit

|

A zero waste audit is the "micro" view of an organization's waste. It provides the full value stream for specific materials found in the waste stream, from purchase through use and disposal. The audit samples the material at it's entry point into the facilities waste systems and interviews it's purchasers and users, asking:

|

A well executed zero waste audit identifies the individuals and the decisions they made along each object's path, as well as the costs incurred for it's purchase, use and disposal. It provides the full cost of use data needed to eliminate the need for materials, reduce their rate of consumption, or change the material to one that can be reused or reprocessed. Benefits are primarily cost savings, but can include reduced contamination rates.